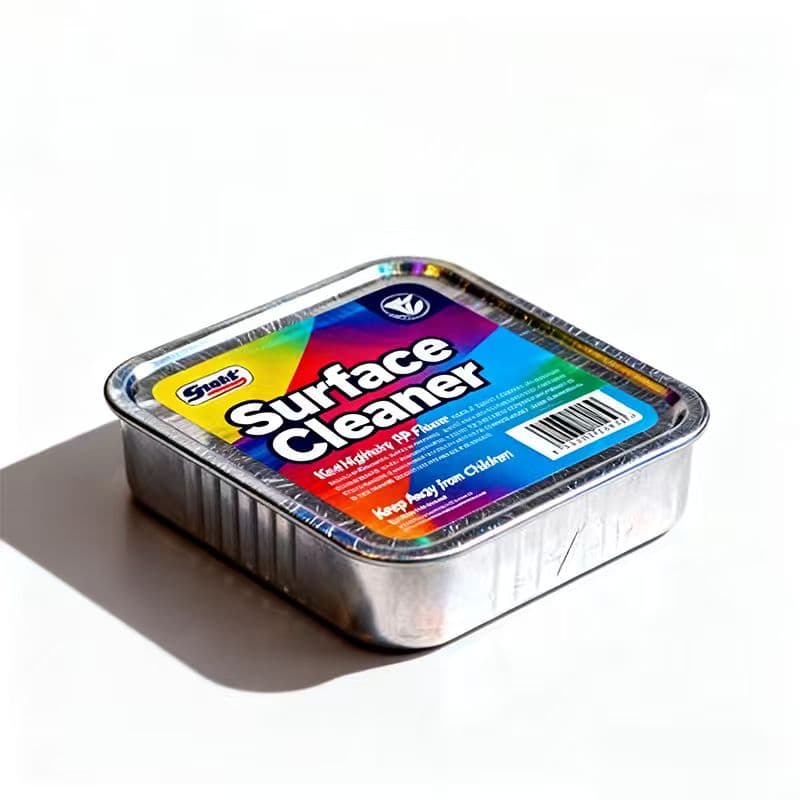

Label Materials for Rigid Containers

The label material utilizes high-strength PP or PET-based film, offering exceptional clarity, rigidity, and solvent resistance. It adheres effectively to plastic, glass, and metal containers, maintaining secure attachment and print stability during filling, transportation, and consumer use. The label must remain smooth and intact even under high humidity, temperature fluctuations, and exposure to cleaning agents, ensuring long-term readability and brand visibility.

These labels are engineered to resist peeling, fading, and edge lifting while supporting high-resolution printing for vibrant graphics, safety instructions, and barcode identification. The material surface accommodates UV flexographic, digital, or thermal transfer printing, delivering excellent ink adhesion and chemical durability.

Home care and laundry labels for rigid packaging are also referred to as detergent bottle labels, household cleaner labels, hard-surface container labels, disinfectant bottle self-adhesive labels, and chemical-resistant packaging labels.

The adhesive system typically employs solvent acrylic or hot-melt permanent adhesive, formulated to provide strong initial tack and lasting adhesion to low-energy plastics such as HDPE or PP. This ensures reliable bonding even in wet or humid conditions, maintaining a clean appearance without curling or bubbling.

Specifically, the synthetic film used for rigid container labels consists of polyolefin or polyester resins, manufactured through extrusion and surface treatment technology to achieve high stiffness, transparency, and print receptivity. It combines the durability of plastic with the print quality of paper, making it ideal for premium household and industrial cleaning product labeling.

Interested in this product?

Get in touch for more information, pricing, or custom requirements.